FLAGSHIP PROJECT

Methanol to Jet SAF Energy Park

Victoria or South Australia

LOCATION: Victoria or South Australia

Australia’s First Large Scale Methanol to Jet Facility. The SAF Energy Park converts low carbon methanol into sustainable aviation fuel (SAF) to decarbonise and unlock production scale for the aviation industry. It also produces other products such as renewable diesel.

PRODUCTION RATE

Amount

140 mlpa

PRODUCTION RATE

Pre-FEED

PROJECT STAGE

Methanol to Jet (SAF)

PATHWAY

150+ approx

JOBS CREATED

PRODUCTION RATE

Amount

PRODUCTION RATE

140 mlpa

PROJECT STAGE

Pre-FEED

PATHWAY

Methanol to Jet (SAF)

JOBS CREATED

150+ approx

Victoria or South Australia

Victoria or South Australia

Victoria or South Australia

About Project

About Project

About Project

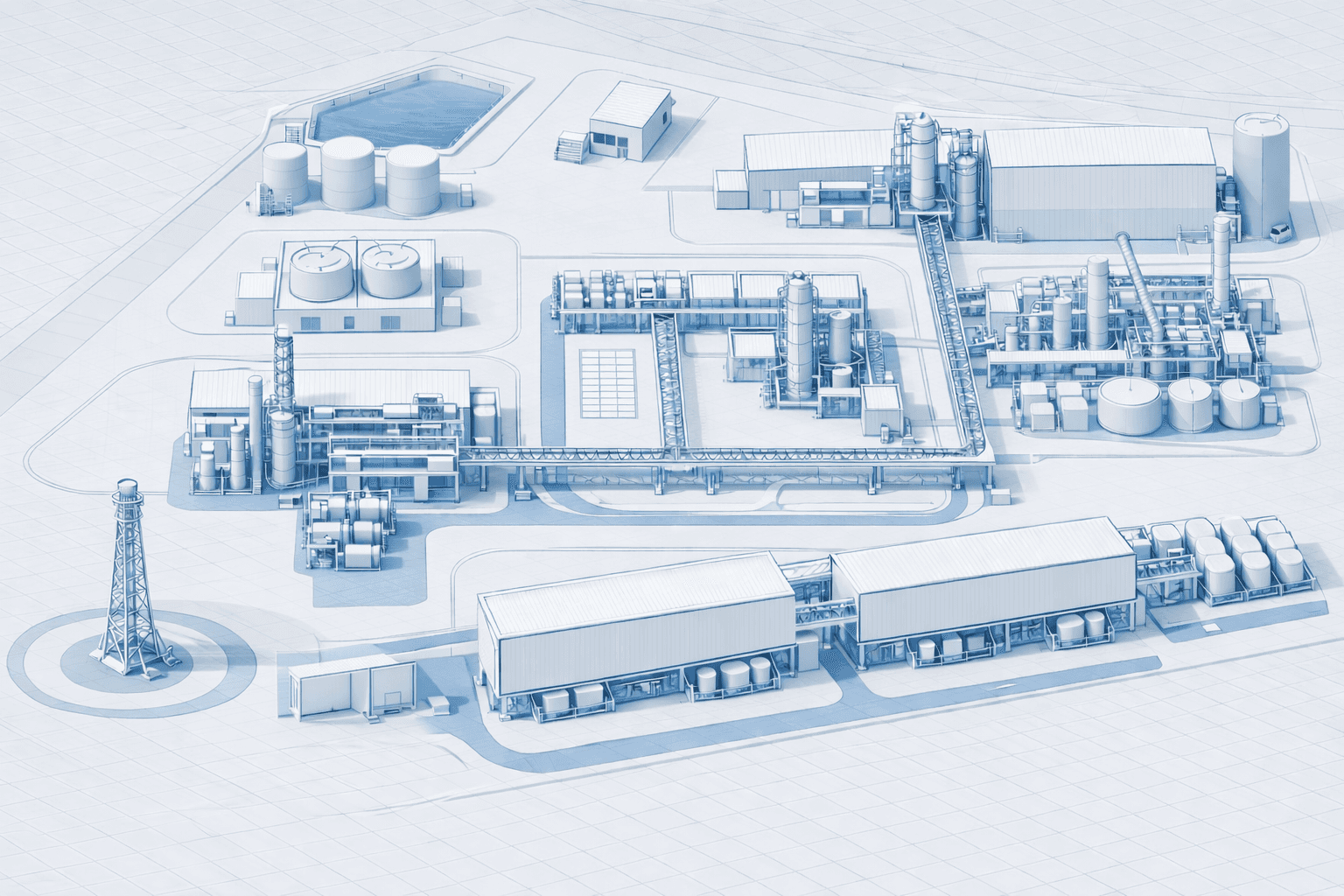

The SAF Energy Park is a breakthrough facility designed to produce drop-in Sustainable Aviation Fuel (SAF) to decarbonise the aviation sector.

HAMR Energy completed a successful feasibility study for the $700–$800 million facility in 2025, identifying the Methanol-to-Jet (MtJ) pathway as the most scalable solution to meet the global SAF supply shortfall. Located in either South Australia or Victoria, the plant will serve as a centralised refining hub for low-carbon methanol produced at HAMR Energy’s regional biomass to methanol sites around the region, such as Portland Renewable Fuels.

The facility is engineered to convert 300,000 tonnes of low-carbon methanol, made from forestry residues and renewable energy, into 125 million litres of SAF per year. This volume of fuel is equivalent to decarbonising approximately 3.5 million economy-class passenger trips from Sydney to Melbourne annually.

Our vertically integrated "Hub & Spoke" model manages the entire production lifecycle transforming under-utilised forestry resources into drop-in sustainable aviation fuel. This approach secures a domestic supply chain for SAF and will help produce competitive supply for airlines, a scalable solution to address the projected 10-million-tonne global SAF supply shortfall from 2030.

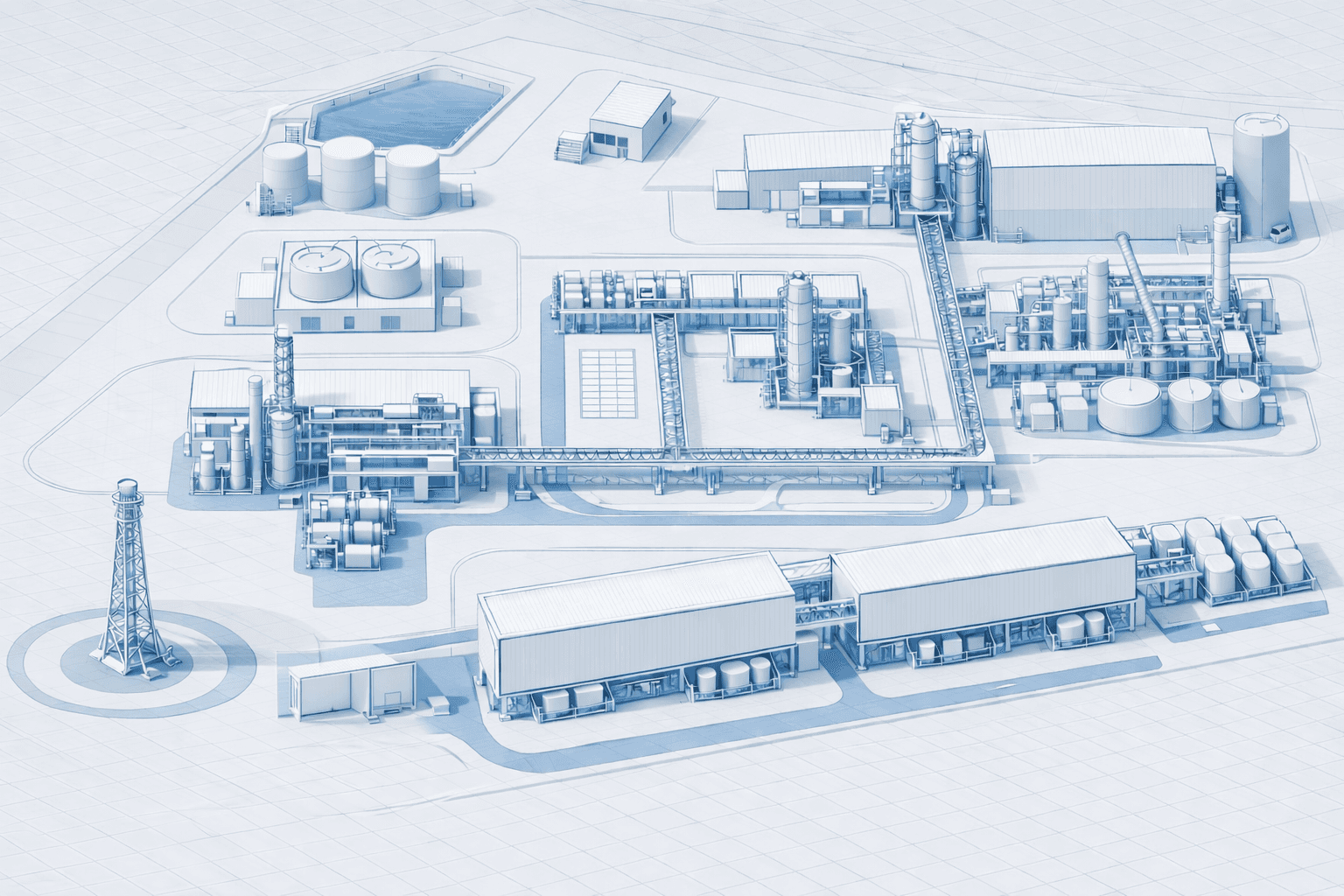

The SAF Energy Park is a breakthrough facility designed to produce drop-in Sustainable Aviation Fuel (SAF) to decarbonise the aviation sector.

HAMR Energy completed a successful feasibility study for the $700–$800 million facility in 2025, identifying the Methanol-to-Jet (MtJ) pathway as the most scalable solution to meet the global SAF supply shortfall. Located in either South Australia or Victoria, the plant will serve as a centralised refining hub for low-carbon methanol produced at HAMR Energy’s regional biomass to methanol sites around the region, such as Portland Renewable Fuels.

The facility is engineered to convert 300,000 tonnes of low-carbon methanol, made from forestry residues and renewable energy, into 125 million litres of SAF per year. This volume of fuel is equivalent to decarbonising approximately 3.5 million economy-class passenger trips from Sydney to Melbourne annually.

Our vertically integrated "Hub & Spoke" model manages the entire production lifecycle transforming under-utilised forestry resources into drop-in sustainable aviation fuel. This approach secures a domestic supply chain for SAF and will help produce competitive supply for airlines, a scalable solution to address the projected 10-million-tonne global SAF supply shortfall from 2030.

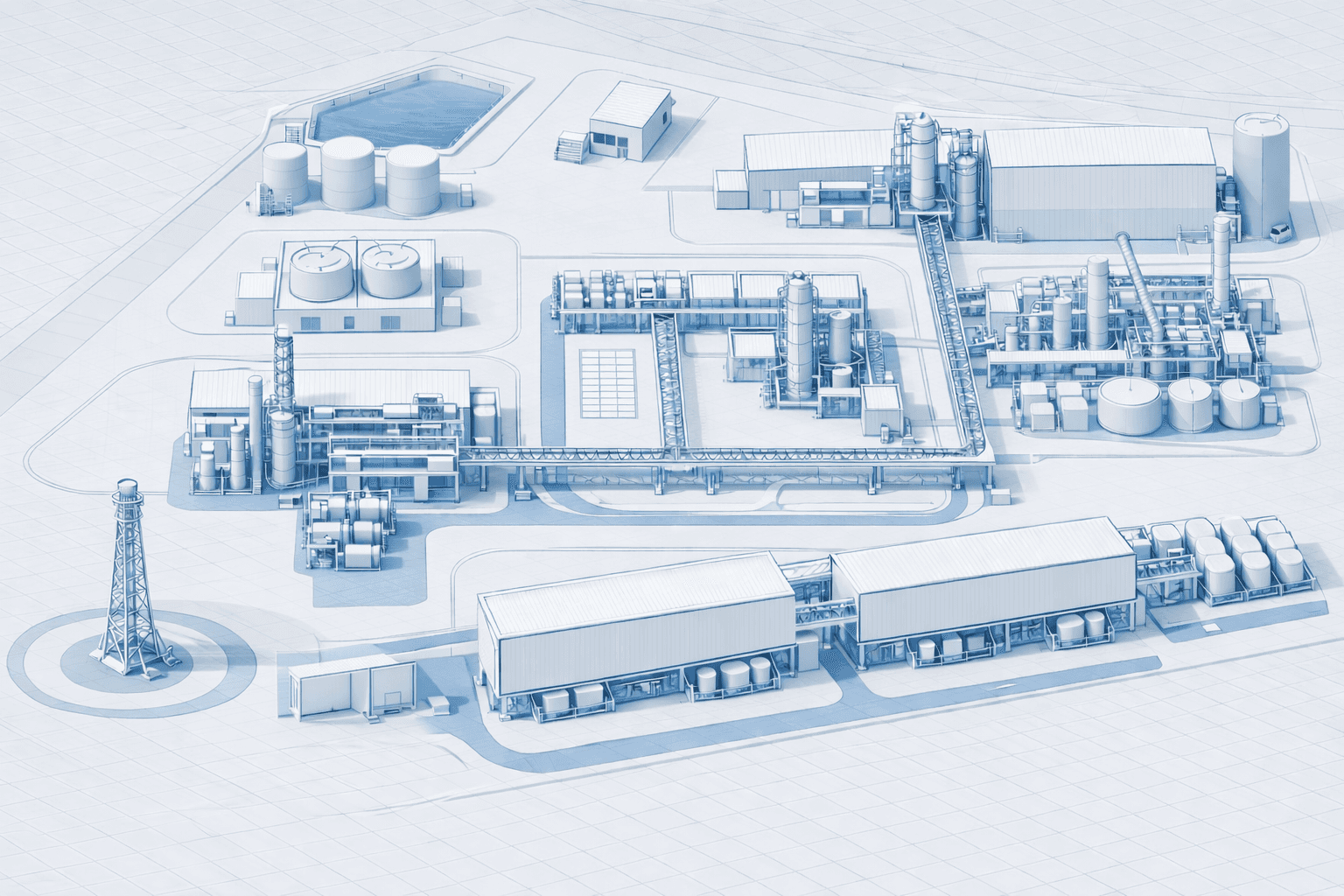

The SAF Energy Park is a breakthrough facility designed to produce drop-in Sustainable Aviation Fuel (SAF) to decarbonise the aviation sector.

HAMR Energy completed a successful feasibility study for the $700–$800 million facility in 2025, identifying the Methanol-to-Jet (MtJ) pathway as the most scalable solution to meet the global SAF supply shortfall. Located in either South Australia or Victoria, the plant will serve as a centralised refining hub for low-carbon methanol produced at HAMR Energy’s regional biomass to methanol sites around the region, such as Portland Renewable Fuels.

The facility is engineered to convert 300,000 tonnes of low-carbon methanol, made from forestry residues and renewable energy, into 125 million litres of SAF per year. This volume of fuel is equivalent to decarbonising approximately 3.5 million economy-class passenger trips from Sydney to Melbourne annually.

Our vertically integrated "Hub & Spoke" model manages the entire production lifecycle transforming under-utilised forestry resources into drop-in sustainable aviation fuel. This approach secures a domestic supply chain for SAF and will help produce competitive supply for airlines, a scalable solution to address the projected 10-million-tonne global SAF supply shortfall from 2030.

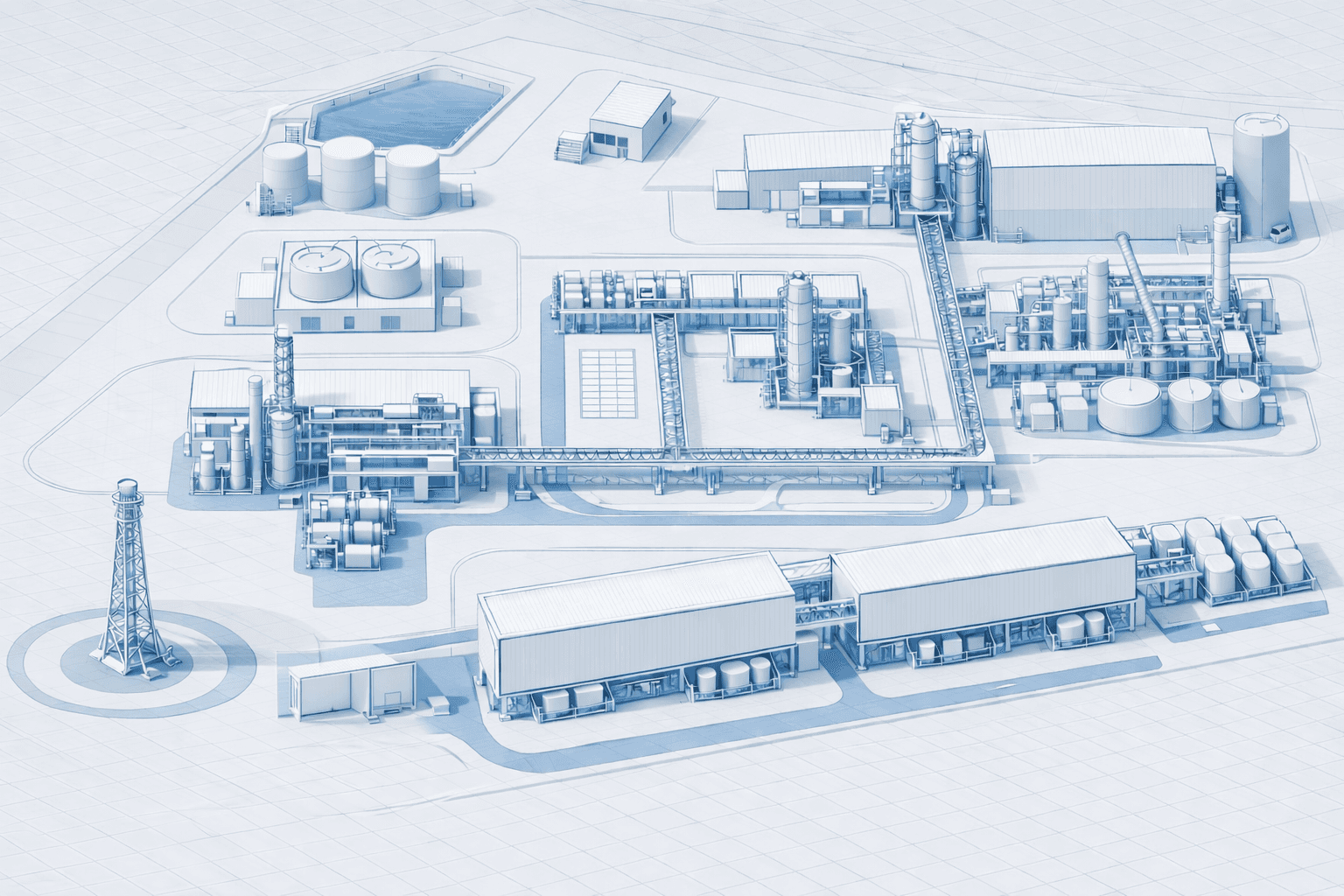

The SAF Energy Park is a breakthrough facility designed to produce drop-in Sustainable Aviation Fuel (SAF) to decarbonise the aviation sector.

HAMR Energy completed a successful feasibility study for the $700–$800 million facility in 2025, identifying the Methanol-to-Jet (MtJ) pathway as the most scalable solution to meet the global SAF supply shortfall. Located in either South Australia or Victoria, the plant will serve as a centralised refining hub for low-carbon methanol produced at HAMR Energy’s regional biomass to methanol sites around the region, such as Portland Renewable Fuels.

The facility is engineered to convert 300,000 tonnes of low-carbon methanol, made from forestry residues and renewable energy, into 125 million litres of SAF per year. This volume of fuel is equivalent to decarbonising approximately 3.5 million economy-class passenger trips from Sydney to Melbourne annually.

Our vertically integrated "Hub & Spoke" model manages the entire production lifecycle transforming under-utilised forestry resources into drop-in sustainable aviation fuel. This approach secures a domestic supply chain for SAF and will help produce competitive supply for airlines, a scalable solution to address the projected 10-million-tonne global SAF supply shortfall from 2030.

Scale & Impact: 125 million litres of SAF annually, plus by-products such as renewable diesel

Scale & Impact: 125 million litres of SAF annually, plus by-products such as renewable diesel

Proven Technology: Built with commercial, scalable technology partner Honeywell UOP

Proven Technology: Built with commercial, scalable technology partner Honeywell UOP

Feedstock Security: Agreements in place covering > 100% of required input

Feedstock Security: Agreements in place covering > 100% of required input

Major piece of energy infrastructure investment, creating hundreds of jobs and supporting Australia's fuel security for the future

Major piece of energy infrastructure investment, creating hundreds of jobs and supporting Australia's fuel security for the future

Scale & Impact: 125 million litres of SAF annually, plus by-products such as renewable diesel

Proven Technology: Built with commercial, scalable technology partner Honeywell UOP

Feedstock Security: Agreements in place covering > 100% of required input

Major piece of energy infrastructure investment, creating hundreds of jobs and supporting Australia's fuel security for the future

Scale & Impact: 125 million litres of SAF annually, plus by-products such as renewable diesel

Proven Technology: Built with commercial, scalable technology partner Honeywell UOP

Feedstock Security: Agreements in place covering > 100% of required input

Major piece of energy infrastructure investment, creating hundreds of jobs and supporting Australia's fuel security for the future

Project Timeline

Project Timeline

Project Timeline

The SAF Energy Park has recently completed its Feasibility stage with technology partner Honeywell UOP. This means the project is both technically and financially viable and ready to enter the next stage of development, pre-FEED.

The Methanol to Jet site will integrate the world's most trusted names in engineering and technology to ensure financial bankability and operational reliability.

|

|---|

Honeywell UOP is the global process-technology arm of Honeywell, a 100-year global leader in refining and petrochemical technologies. Honeywell UOP will deliver the commercial methanol-to-jet eFining solution that makes large-scale, certified SAF possible. |

World Class Technology Partners

World Class Technology Partners

The Methanol to Jet site will integrate the world's most trusted names in engineering and technology to ensure financial bankability and operational reliability.

|

|---|

Honeywell UOP is the global process-technology arm of Honeywell, a 100-year global leader in refining and petrochemical technologies. Honeywell UOP will deliver the commercial methanol-to-jet eFining solution that makes large-scale, certified SAF possible. |

The SAF Energy Park has recently completed its Feasibility stage with technology partner Honeywell UOP. This means the project is both technically and financially viable and ready to enter the next stage of development, pre-FEED.

The SAF Energy Park has recently completed its Feasibility stage with technology partner Honeywell UOP. This means the project is both technically and financially viable and ready to enter the next stage of development, pre-FEED.

The SAF Energy Park has recently completed its Feasibility stage with technology partner Honeywell UOP. This means the project is both technically and financially viable and ready to enter the next stage of development, pre-FEED.

World Class Technology Partners

The Methanol to Jet site will integrate the world's most trusted names in engineering and technology to ensure financial bankability and operational reliability.

|

|---|

Honeywell UOP is the global process-technology arm of Honeywell, a 100-year global leader in refining and petrochemical technologies. Honeywell UOP will deliver the commercial methanol-to-jet eFining solution that makes large-scale, certified SAF possible. |

Location

LOCATION

TBC - SA or VIC

Project Stage

PROJECT STAGE

Pre-FEED

Production Rate

PRODUCTION RATE

140 mlpa

Pathway

PATHWAY

Methanol to Jet (SAF)

Jobs Creation

JOBS CREATED

150+ approx

Location

TBC - SA or VIC

Project Stage

Pre-FEED

Production Rate

140 mlpa

Pathway

Methanol to Jet (SAF)

Jobs Creation

150+ approx

LOCATION

Portland, Victoria

PRODUCTION RATE

300 KTPA

PROJECT STAGE

Early FEED

PATHWAY

Biomass to Methanol

JOBS CREATED

180+

LOCATION

Portland, Victoria

PRODUCTION RATE

300 KTPA

PROJECT STAGE

Early FEED

PATHWAY

Biomass to Methanol

JOBS CREATED

180+

OUR PROJECTS

OUR PROJECTS

OUR PROJECTS